MENUMENU

- Ocean Monitoring

-

-

Environmental Monitoring Systems

-

-

- Ocean Power

- Company

-

-

Navigation

-

- Service

- News

- Jobs

- Downloads

- Contact

-

English

English

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.

Call Us: +(49) 431-22039-880

Mail Us: info@subctech.com

Inspection sensors and condition monitoring for pCO2 and other parameters to measure sea water quality.

We introduce our OceanXpert-family:

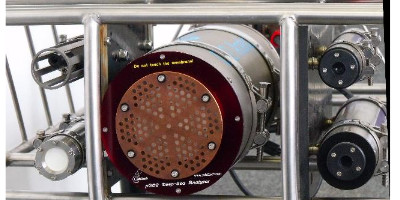

OceanXpert-Sea (Precise subsea pCO2 or CH4 Analyzer, IR or Laser)

OceanXpert-Lab (Precise flow-through pCO2 and/or CH4 Analyzer, IR or Laser)

OceanXpert-Air (Precise, independent Air-CO2 Analyzer, IR)

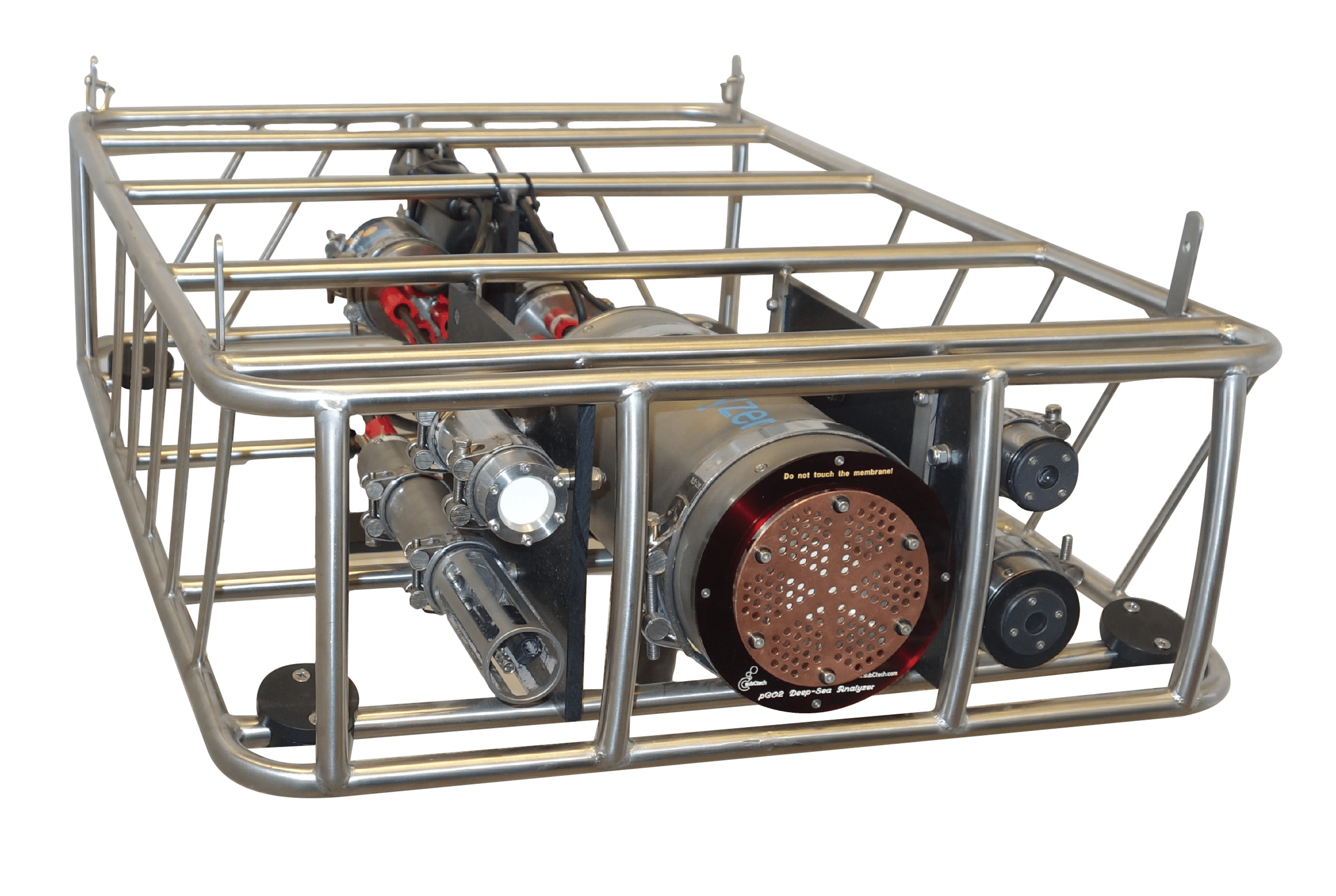

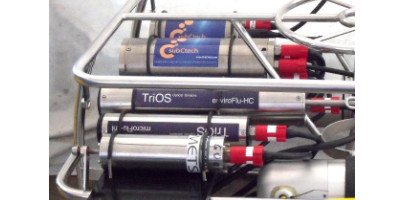

Inspection-sensor-pack with ROV support frame incl. pCO2 analyzer (SubCtech), CTD (Sea&Sun), Methane sensor (Franatech), Oil-in-Water PAH fluorometer (TriOS), Algae-Fluorometer (TriOS). Connected to subsea SmartDI® DataLogger and subsea ROV power supply unit (not visible, in the background)

Example for fish-farming sensors: Chlorophyll-a, Methane, Oil-In-Water (other on request)

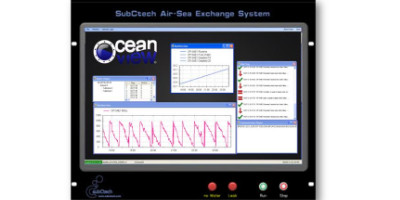

Special processing software → OceanView 4 provides real-time data, alerts and logging

Set of instrumentation frame for deployments under difficult subsea conditions. Consists of different sensors and the MicroDI™ data logger

Example sensors: Chlorophyll-a, Methane, Oil-In-Water (PAH), CTD – other on request

SubCtech provides mostly all sensors. Only the accessories, additional PowerPacks™ or data acquisition, special holder or water adapter makes the products valuable

© 2021 All Rights Reserved by SubCtech GmbH. Imprint - Privacy Policy