MENUMENU

- Ocean Monitoring

-

-

Environmental Monitoring Systems

-

-

- Ocean Power

- Company

-

-

Navigation

-

- Service

- News

- Jobs

- Downloads

- Contact

-

English

English

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.

Call Us: +(49) 431-22039-880

Mail Us: info@subctech.com

We are happy to announce the release of the latest evolution of our OceanPack-family. In cooperation with our partners and clients, we evolved our technology but kept the basic concept of a robust, compact and user-friendly instrument, made for scientific environmental observations.

For the OceanPack CUBE we combined the best of the OceanPack Mobile and the OceanPack Classic. As a result, the instrument is more robust, lighter, very compact and uses the 19” format, which is established as an industrial standard. Versatility, easy handling and expandability are also key features of the CUBE.

The OceanPack™ 19” CUBE is a mobile “Underway” or “FerryBox” autonomous measuring system. The OceanPack™ CUBE includes everything to run unattended and measure water parameters: power supply, data logger, water system and space to include optional sensors. The CUBE system is based on the OceanPack classic rack, but is a mobile, lighter and smaller version. Even though the system is compact, additional sensor can be integrated. Robust against sediments or bio-fouling, just clean with tap water. Optionally, the automatic cleaning can be connected as an external additional device. Quick-connect water tube connections without the need to use tools. Efficient de-airing with our Debubbler mBubbler®. Space to install additional sensors into the Debubbler to measure true water values in one water tank.

OceanPack™ CUBE without Flight-Case (light-weight)

Optional external module for OceanPack™ CUBE to clean the water supply automatically. Two motor-ball valves are used to run the water in a circle. Acid is used to remove fouling very efficiently. If tap water is available, another phase of cleaning with tap water is included. The cleaning can be fully configured to your needs and is suitable for mostly any sensors such as pH, pCO2 etc. Not harmful for the environment. Fully installed and pre-programmed.

Independent controller to open or close the water inlet valve or optionally up to 3 water valves, e.g. water inlet, water outlet and another water inlet. Closes automatically in case of water leak or OceanPack™ stop condition. Will stop the OceanPack™ if the valves are closed. Incl. integrated uninterrupted power supply to close all valves in case of ship power fails.

External controller to open or close the water inlet valve or optionally up to 3 water valves, e.g. water inlet, water outlet and another water inlet. Water-Intake stations can be combined to realize sequentially sample locations.

Outlet tank for installations below the water line to realize a pressure-free outlet e.g. for the nutrient analyzers. Automatic flushing, pump included. Level detector with alarm send signal to data logger (e.g. OceanPack™ system). Not required, if the outlet is driven by gravity (pressure free) or by pump at the same level (pressure neutral) direct to the sea. Required for wet-chemical Nutrient analyzers, if the outlet is not 100% driven by gravity.

The system state (e.g. OceanPack™) can be remote displayed at any location. The Signal-Box can be mount e.g. at the chief engineer’s room on board or water lab etc. Signal lights for “Ok”, “Off” and optional warnings such as “Bad Water Quality” or “System Error”. The Signal-Box is connected with RS-485 up to 5000m. Power is provided local at the Signal-Box. Optional, power can be provided from the data cable, but is limited to max. 100m cable length.

The system (e.g. OceanPack™) can be remote controlled from any location. The Control-Box can be mount e.g. at the chief engineer’s room on board or water lab etc. Signal lights for “Ok”, “Off” and optional warnings such as “Bad Water Quality” or “System Error”. Control buttons for “Run” and “Stop” to operate the remote system, e.g. OceanPack™. The Control-Box is connected with RS-485 up to 5000m. Power is provided local at the Control-Box. Optional, power can be provided from the data cable, but is limited to max. 100m cable length..

The system state (e.g. OceanPack™) can be remote displayed at any location. The Display-Box can be mount e.g. at the chief engineer’s room on board or water lab etc. Messages for “Ok”, “Off” and optional warnings such as “Bad Water Quality” or “System Error” are displayed. The Display-Box is connected with RS-485 up to 5000m. Power is provided local at the Display-Box. Optional, power can be provided from the data cable, but is limited to max. 100m cable length.

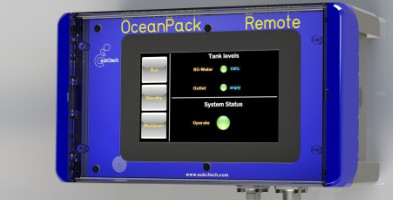

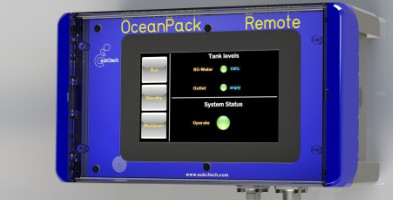

The system (e.g. OceanPack™) can be remote controlled from any location. The Control-Box can be mount e.g. at the chief engineer’s room on board or water lab etc. Messages for “Ok”, “Off” and optional warnings such as “Bad Water Quality” or “System Error” are displayed. Control soft buttons for “Run” and “Stop” etc. to operate the remote system, e.g. OceanPack™. The Control-Box is connected with RS-485 up to 5000m. Power is provided local at the Control-Box. Optional, power can be provided from the data cable, but is limited to max. 100m cable length..

19” rack Data-Server. Actual industrial PC hardware, running MS-Windows®, incl. 19” Video monitor, front IP65 protected; Wall mounting holder. Interface to the OceanPack™ or user systems.

Passenger information display without signal lights and without control elements. The display is protected and locked against any operation and user action from outside. Typically wall mounting holder, other or special on request. Interface to the OceanPack™ or user systems..

© 2021 All Rights Reserved by SubCtech GmbH. Imprint - Privacy Policy