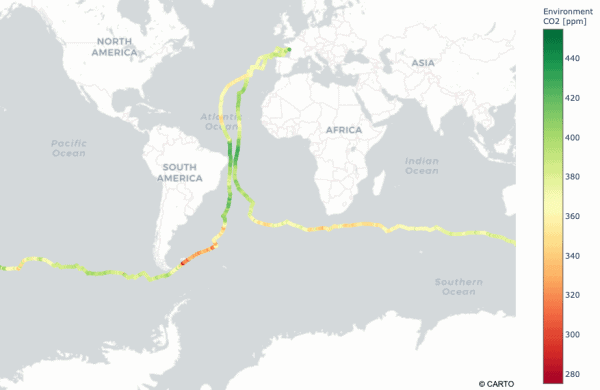

OceanPack™ flow-through (inline) systems are also known as “FerryBox” or “Underway” systems. They measure all types of environmental parameters in sea water or fresh water such as temperature, salinity, dissolved oxygen (DO), pH value, pCO2, turbidity, nutrients and many more. A separate 19″ cabinet is available for high-precision wet-chemical nutrient analysis. Samplers for water (SubCtech’s ship-water-sampler) or filtration units for micro-plastics (SubCtech’s MP-Sampler) can also be operated.

In contrast to classical in-situ probes, all probes in the OceanPack™ are directly accessible and protected, service is simplified, and unattended operating times increase significantly.

Standardized technology for exact measurements

OceanPack™ systems can be used on any type of ship, in containers or laboratories, for science, authorities or industry.

OceanPack™ systems are standardized in 19″ technology to enable high modularity and simplified cost-efficient maintenance. In particular, simple operation on board under difficult conditions and short service times are essential features.

Our latest OceanPacks™ generation is the result of a continuous process of optimization and quality control. During the design process, we put emphasis on reliability, robustness, user-friendliness and cost-effectiveness.

To operate, OceanPacks™ are simply switched on or off without any further setup procedures. A control lamp signals with green “ok” and red “error” or “warning”. The operation and display of operating states can also be carried out by remote controls, e.g. by the ship engineer or from the ship’s helm or water laboratory.

To operate, OceanPacks™ are simply switched on or off without any further setup procedures. A control lamp signals with green “ok” and red “error” or “warning”. The operation and display of operating states can also be carried out by remote controls, e.g. by the ship engineer or from the ship’s helm or water laboratory.

The front door has an inspection windows so that the status can be checked quickly during routine tours by technicians. The OceanPack™ is protected against water jets, and still splash-proof even when open. Dampers protect against shocks and vibrations on ships.

As requested by our customers, we made all probes inside the OceanPack™ easily accessible. We streamlined the service procedures, resulting in significantly increased unattended operation times and reduced operation costs.

All components of the larger rack systems are mounted on movable drawers, the side doors can be removed. This means that all components can be reached on board even in confined spaces.

Due to our long-lasting expert-knowledge we are able to design a tailored underway system for your vessel. A purpose designed water supply is key for quality measurements. Our OceanPack™ can be connected with the ship’s sea water supply or rely on its own pumps. We offer solutions for installations below and above the water line and provide advice in the best applied pump technology: depending on your setup we install maintenance-free circulation pumps, self-priming membrane pumps or low-flow peristaltic pumps.

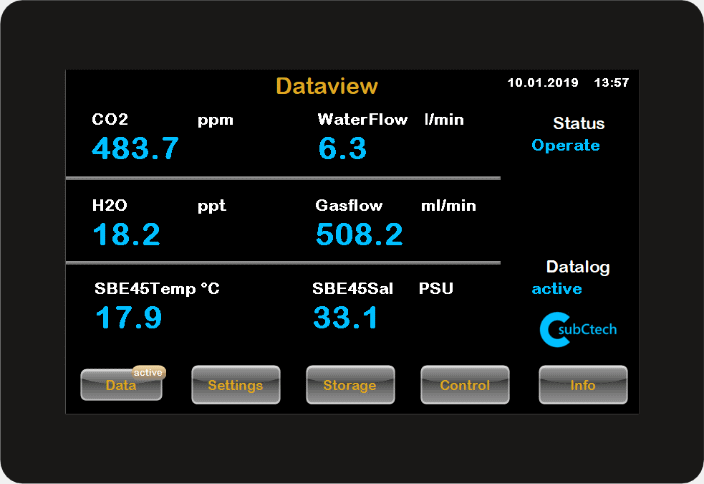

A 7″ touchscreen gives you full control of the system by providing a comprehensive overview of the operating status and all incoming data. If required, deep diagnostic menus can be used. Configurations can also be changed using simple, intuitive menus.

A 7″ touchscreen gives you full control of the system by providing a comprehensive overview of the operating status and all incoming data. If required, deep diagnostic menus can be used. Configurations can also be changed using simple, intuitive menus.