MENUMENU

- Ocean Monitoring

-

-

Environmental Monitoring Systems

-

-

- Ocean Power

- Company

-

-

Navigation

-

- Service

- News

- Jobs

- Downloads

- Contact

-

English

English

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.

Call Us: +(49) 431-22039-880

Mail Us: info@subctech.com

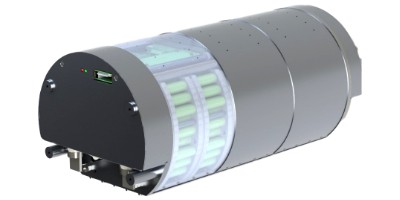

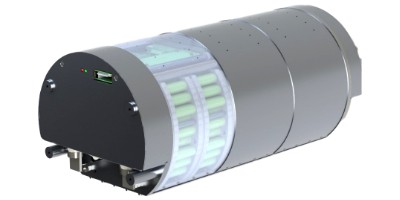

The batteries are assembled from SmartPowerBlocks™ (SPB), each of which is protected and monitored by its own SmartBMS™ slave. This keeps energy, weight and voltage small, and service is simplified. Different battery configurations can be implemented by selecting the voltage level of the SPB and connecting different number of SPBs. The SmartBMS™ Master provides all superordinate functions and monitors the entire system. An optional CIM (Customer Interface Module) allows batteries and components to be interconnected, such as embedded charger, power distribution units (PDU), additional batteries (via junction box), system interface to the higher-level system, and operation of one or more top-side 19″ PowerChargers™.

The batteries are partly type-qualified according to MIL-STD. The batteries can be additionally qualified to UN T38.3 on request.

The modular battery for AUV or other vehicle has a diameter of 260mm (without pressure housing). The modules are type-qualified according to MIL-STD. The modules can be additionally qualified to UN T38.3 on request. In the HV version, the modules are stacked to achieve higher voltages with lower currents.

The modular battery for AUV or other vehicle has a diameter of 260mm (without pressure housing). The modules are type-qualified according to MIL-STD. The modules can be additionally qualified to UN T38.3 on request. In the LV version, the modules are parallel connected for low voltages with higher currents.

The modular battery for AUV or other vehicle has a diameter of 310mm (without pressure housing). The modules are fully qualified according to MIL-STD. The modules can be additionally qualified to UN T38.3 on request. In the HV version, the modules are stacked to achieve higher voltages with lower currents.

The modular battery for AUV or other vehicle has a diameter of 310mm (without pressure housing). The modules are fully qualified according to MIL-STD. The modules can be additionally qualified to UN T38.3 on request. In the LV version, the modules are parallel connected for low voltages with higher currents, particularly for high energy applications.

The modular battery for AUV or other vehicle has a diameter of 416mm (without pressure housing). The modules correspond to the MIL-STD qualified 310mm modules and can be fully qualified according to UN T38.3, MIL-STD or API17F on request. In the HV version, the modules are stacked to achieve higher voltages with lower currents.

The modular battery for AUV or other vehicle has a diameter of 416mm (without pressure housing). The modules correspond to the MIL-STD qualified 310mm modules and can be fully qualified according to UN T38.3, MIL-STD or API17F on request. In the LV version, the modules are parallel connected for low voltages with higher currents, particularly for high energy applications.

We offer customized batteries, or vehicle batteries based on standard batteries (COTS, commercial off-the-shelf). Typical sizes are 150mm to 230mm (without pressure housing). The voltage levels can be adjusted. For COTS batteries, please note that the current is limited. Without the special properties of our special vehicle batteries, self-heating must be given special consideration. The batteries are normally constructed without division and do not include SmartPowerBlock™, and therefore have no redundancy at the module level The SmartBMS™ provides all necessary functions and monitors the battery. An optional CIM (Customer Interface Module) allows different modules to be interconnected, such as embedded charger, power distribution units (PDU), additional batteries (via junction box), system interface to the higher-level system, and operation of a top-side 19" PowerCharger™.

We offer customized batteries with special shapes, to make optimal use of the available space. The voltage levels can be adjusted. Without the special properties of our special vehicle batteries, self-heating must be given special consideration. The SmartBMS™ provides all necessary functions and monitors the battery. An optional CIM (Customer Interface Module) allows different modules to be interconnected, such as embedded charger, power distribution units (PDU), additional batteries (via junction box), system interface to the higher-level system, and operation of a top-side 19" PowerCharger™.

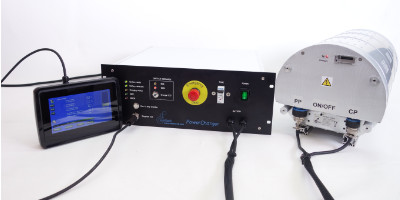

High-power, high safety, highly reliable charger for SmartBMS™ Li-Ion battery in switching mode technology. Two power-channels for redundancy are supported by two independent charger power supplies.

© Houston Mechatronics

© SubseaCraft

150V 9kW peak AUV battery with diagnostic unit and PowerCharger.

The FlatFish project is a venture undertaken by the German Research Center for Artificial Intelligence (DFKI), the Brazilian Institute of Robotics (BIR) and Shell. It aims at designing an autonomous underwater vehicle (AUV) for repeated inspections of oil & gas subsea structures whilst being submerged for extended periods of time. For the evaluation of energy and high-bandwidth data transfer while submerged, the docking station demonstrator was equipped with optical data transmitters and electrical contacts for battery charging, witnessed by representatives from Shell (Rio, Brazil and Houston, USA) and from SENAI-CIMATEC (Salvador, Brazil). ©DFKI/Ground Truth Robotics, Florian Cordes

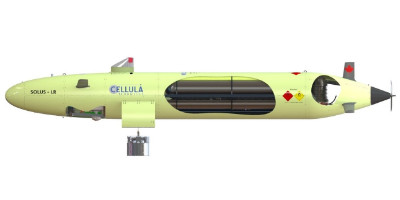

Li-ion battery for a fuel cell UUV. SubCtech has developed and built the Li-Ion battery for an innovative long range Unmanned Underwater Vehicle (UUV). The UUV is being developed by Cellula Robotics Ltd. under the Canadian All Domain Situational Awareness (ADSA) Science & Technology (S & T) Program developed and built. Known as “Solus-LR”, the UUV will have a target range of 2000 km and is designed to stay submerged for multi-month missions. The Li-Ion battery system works with the fuel cell system, taking power peaks and ensuring optimum power system operating parameters. © Cellula Robotics

Amogh – the dependable underwater surveillance vehicle Amogh (Hindi: Dependable Work Horse) is a third generation Autonomous Underwater Vehicle (AUV), designed and being developed in collaboration with Larsen&Toubro, Mumbai (India) and Edgelab, Italy. The AUV is designed to comply with International Hydrographic Organisation Standards for Hydrographic Surveys and IMP regulations for the safety of navigation. The containerized design with built-in LARS and AUV maintenance support system is suitable for ease of deployment and installation. Amogh is loaded with the latest state-of-the-art sensors, payloads, propulsion and energy system, which make it a best-of-class AUV for hydrographic and underwater surveillance, and reconnaissance operations. Endurance 22hrs. © EdgeLab

The $7 million Shell Ocean Discovery XPRIZE is a global competition which challenged teams to advance deep sea technologies for autonomous, fast, high-resolution ocean exploration. Texas A&M student team named finalist in Shell Ocean Discovery XPRIZE competition. Marlin carries an on-board intelligence system, a long-range optical and acoustic communication and reference system, an ultra-high resolution 3-D scanner, inertial navigation system, Doppler velocity tracking, chemical sensors to monitor the environment, a pump jet propulsion for high speed operation, forward dive plane for quick descents and a wave energy conversion system. To operate all of this technology, Marlin is also equipped with a 48 kilowatt-per-hour battery system, which is more than the average household uses per day. © Deep-Down; A&M University (XPRIZE)

An analogous mission as preparation for future explorations of Europa. The project Europa-Explorer is a pilot survey for future missions to Jupiter’s moon Europa. It focuses on the aspect of navigation of robotic systems on and espe-cially under Europa’s surface. Below Europa’s ice shield (thickness between 3 and 15 kilometers) an ocean comprised of liquid water is expected. For the exploration of this ocean a fully-autonomous system is necessary due to the long run-time of communication from earth to Europa (33 to 53 minutes). SubCtech has developed and delivered the battery system. © DFKI, Jan Albiez

Based on the proven Li-Ion rechargeable batteries we offer complete energy systems, for example AUV drive or the on-board electronics. The especially developed electronics SmartBMS™ supports the Li-Ion PowerPack™. The SmartBMS™ monitors the battery with especially for Li-Ion technologies designed switching circuits. NMEA 0183 is a compatible data interface to the AUV host system. This NMEA-0183 interface is easy to adapt and galvanically decoupled.

The AUV PowerPacks™ are available in up to about 100 kWh and 400V. PowerPacks™ can be connected for larger battery capacity. For the optimal design, the AUV PowerPacks™ are adapted to the equipment rack. SubCtech offers sufficient know-how from various past projects from the planning phase onwards. Of course, existing batteries can be replaced with this innovative technology.

Li-Ion batteries can deliver very high currents, in contrast to other battery technologies because of their low internal resistance. Especially produced for the marine sector, our PowerPacks™ work highly efficient at low temperatures.

The PowerPacks™ can be supplied in pressure-resistant titanium housings with an operating depth of up to 6000m. They can also be set in an existing housing.

The SmartChargers™ – specially tuned chargers for the PowerPacks™ – are connected directly and do not have to be further adjusted . The SmartCharger™ technology charges the PowerPacks™ safely and gently without opening the pressure housing. Therefore the AUV can be charged in water.

For additional security, the PowerPacks™ are designed to be fully redundant. This way, 50% of the remaining capacity will always be available in the event of a fatal error, so that the mission can be brought to a regular ending.

© 2021 All Rights Reserved by SubCtech GmbH. Imprint - Privacy Policy