MENUMENU

- Ocean Monitoring

-

-

Environmental Monitoring Systems

-

-

- Ocean Power

- Company

-

-

Navigation

-

- Service

- News

- Jobs

- Downloads

- Contact

-

English

English

Please feel free to contact us. We will get back to you within 1-2 business days. Or just call us now.

Call Us: +(49) 431-22039-880

Mail Us: info@subctech.com

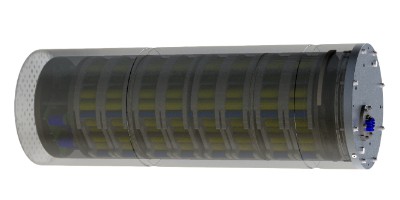

High-Performance, high reliable and high-safety Li-Ion rechargeable battery for offshore subsea electronics. Designed for deployments up to 25 years, the electronic and Li-Ion cells are extreme robust and fail-safe.

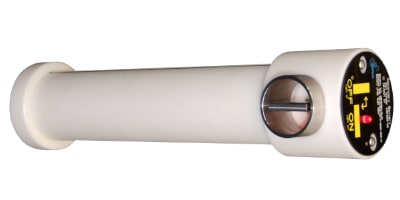

The battery has a 14 V output that can deliver 7A continuously and is charged topside. With an energy of 674Wh, the battery can be used flexibly. The ROV Low-torque rotary switch follows ISO 13628-8:2002-12 (E).

The battery has a 14 V output that can deliver 7A continuously and is charged topside. With an energy of 674Wh, the battery can be used flexibly. Optional ROV low-torque rotary switch according ISO 13628-8:2002-12 (E) available

The battery has a 24V input and a regulated 24V output. The output current is limited to 4A for 120sec.

The battery has a 24V input and a regulated 24V output. The output current is limited to 3A / 70W, without time limit With an energy of 253Wh, the battery can be used flexibly.

High-energy subsea 400V DC online UPS battery with low power 400V DC charge input, 400V DC 1kW output and additional aux. 24V DC output, with optional higher 400V output current. Buffer time 1hour @1kW. Fully qualified according API17F and with transport test UN T38.3

High-power subsea 200V DC UPS battery with low power 200V DC charge input, 200V DC 6.5kW output, with optional higher current. Cycles defined for 45s, 3 cycles every 4 hours. Fully qualified according API17F and with transport test UN T38.3

High-power subsea 400V DC UPS battery with low power 400V DC charge input, 400V DC 6.5kW output, with optional higher current. Cycles defined for 45s, 3 cycles every 4 hours. Fully qualified according API17F and with transport test UN T38.3

High-power subsea 200V DC UPS battery with low power 200V DC charge input, 200V DC 15kW output, with optional higher current. Cycles defined for 45s, 3 cycles every 4 hours. Fully qualified according API17F and with transport test UN T38.3

High-power subsea 400V DC UPS battery with low power 400V DC charge input, 400V DC 15kW output, with optional higher current. Cycles defined for 45s, 3 cycles every 4 hours. Fully qualified according API17F and with transport test UN T38.3

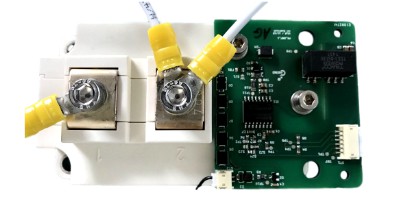

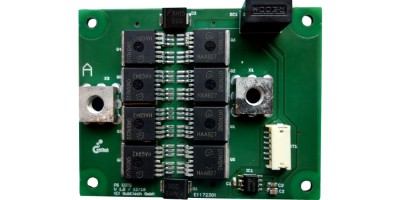

The Power Distributing Unit (PDU) works as Protection, Switch & Fuse for high voltages and high power output controls. The PDU consists of electronic switch (IGBT or Power-MOSFET), “last chance” fuse, current monitoring and a micro-controller to switch the output, and to acquire data such as current and voltage in real-time or on request (polling).

The Power Distributing Unit (PDU) works as Protection, Switch & Fuse for high voltages and high power output controls. The PDU consists of electronic switch (IGBT or Power-MOSFET), “last chance” fuse, current monitoring and a micro-controller to switch the output, and to acquire data such as current and voltage in real-time or on request (polling).

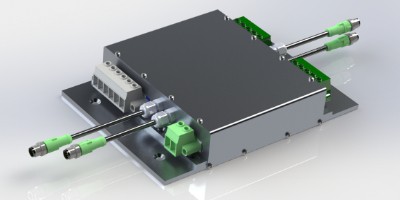

A PDU Power Distribution unit can be integrated in a pressure housing. In the example, 7 PDU channels are integrated with switches (IGBT high voltage or MOSFET low voltage). It is controlled via MODBUS RTU, e.g. with the CIM controller or the SmartBMS. The module can contain various functions. Several batteries or battery modules are interconnected here. The power outputs are distributed to one or more outputs. Optionally, charge balancing takes place, i.e. the charging input is distributed to the batteries for balanced charging. The individual BMS interfaces of the batteries or battery modules are linked and various data outputs are available. These can be made available exclusively to the higher-level system (AUV CPU or SEM), a diagnostic unit or the external charger. The CIM (Custom Interface Module) can be used flexibly for these tasks. There are several interface protocols such as serial RS-232, RS-485 NMEA-0183, MODBUS RTU or CAN / FT available. Of course, all interfaces are galvanic isolated and EMC protected. CAN safety, Modbus TCP or SiiS L2 are planned. The power outputs can be equipped with PDU (Power Distribution Unit) channels. This means that each output is individually switchable and individually protected. Currents, voltages and temperatures as well as short circuits are recorded. External short circuits or an interchanged connection are protected by optional fuses.

The junction box can contain various functions. Several batteries or battery modules are interconnected here. The power outputs are distributed to one or more outputs. Optionally, charge balancing takes place, i.e. the charging input is distributed to the batteries for balanced charging. The individual BMS interfaces of the batteries or battery modules are linked and various data outputs are available. These can be made available exclusively to the higher-level system (AUV CPU or SEM), a diagnostic unit or the external charger. The CIM (Custom Interface Module) can be used flexibly for these tasks. There are several interface protocols such as serial RS-232, RS-485 NMEA-0183, MODBUS RTU or CAN / FT available. Of course, all interfaces are galvanic isolated and EMC protected. CAN safety, Modbus TCP or SiiS L2 are planned. The power outputs can be equipped with PDU (Power Distribution Unit) channels. This means that each output is individually switchable and individually protected. Currents, voltages and temperatures as well as short circuits are recorded. External short circuits or an interchanged connection are protected by optional fuses.

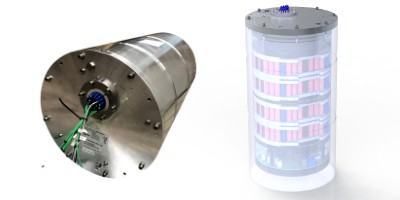

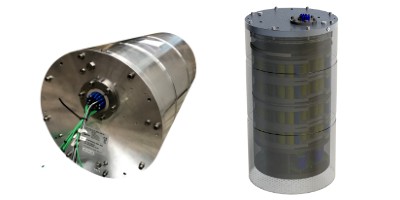

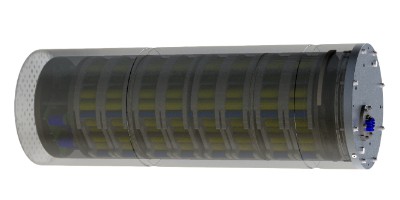

Rechargeable Li-Ion batteries are amongst the most efficient batteries. They are ideal for the use in marine and offshore technology. They provide the highest capacity while being of low weight and volume. SubCtech produces complete battery packs, the PowerPacks™, in cooperation with manufacturers of high-class and certificated industrial cells. The PowerPacks™ are easy and safe to operate with the matching charging technology SmartCharger™.

Our Li-Ion batteries are used like standard batteries. An electronic circuit provides that the batteries run smoothly. The PowerPacks™ switch off at low voltage to prevent damage. The operation disconnects for the time of the defective condition in case of overcurrent or short circuit.

Li-Ion batteries can deliver high current, in contrast to other battery technologies. PowerPacks™ are chosen especially for the marine industry and work much more efficiently than for instance Alkali prime batteries or Ni-Mh batteries, even at very low temperatures.

The PowerPacks™ are offered on different standard configurations. The rugged and corrosion-free housing made of titanium or POM and can be used in depths of up to 6000m.

Connect the battery to the SmartCharger™ and leave it attached until the green light indicates to be fully charged. A special handling is unnecessary. The SmartCharger™ technology enables a safe and gentle charging of the PowerPacks™. The housing can remain closed during this process. Thus, the packs can even be charged built in or in water.

The Li-Ion batteries are already profitable after the third charging process. They are environmentally friendly. Good operating data of the Li-Ion technology simplify projects and usage. Under rough conditions – such as very low temperatures, high currents (also peaks) or under difficult offshore conditions – our Li-Ion PowerPacks™ provide more power than Alkali primary cells or older storage battery technologies. The easy handling is an important characteristic that makes our PowerPacks™ ideal for usage on board or under extreme conditions like under ice or in the deep ocean.

© 2021 All Rights Reserved by SubCtech GmbH. Imprint - Privacy Policy